Menu

free shipping on orders over £100

free shipping on orders over £100

Single-use disposable gloves provide a basic barrier between and everyday hazards. Dependant on application, these may range from food handling, medical use through to handling chemicals. The following summary will guide you to the best choice of single-use product.

During the COVID-19 pandemic, supply of disposable gloves was thrown completely by the huge spike in global demand. This resulted in manufacturers scrambling to produce product at any cost. For a period, any product would do, it was a case of taking what was available and this has left a legacy.

Since returning to relative normality, supply now far exceeds demand and the market has become saturated with product, often sub-standard posing significant risks to users.

When reviewing your site use of disposable gloves, consider the following 4 points:

A) ENVIRONMENT: Does your workplace use industrial or medical grade products.

B) TASK: Does the wearer require dexterity when wearing the glove?

C) RISK: What are you protecting against? Does the glove need to be chemical resistant or food-safe?

D) FREQUENCY: Will the glove be used repeatedly, or as a one-off? If handling chemicals, are you protecting against splashes or longer contact with the substance?

The ideal single-use disposable product will likely be determined by a combination of these characteristics:

Whilst many sub-par products can be tested (and passed) for chemical resistance, grip or food-safe qualities, cost savings are often made in thickness. The higher the thickness, the better the durability and chemical resistance and the longer it will take for liquid to permeate through the glove. In some cases, a lower thickness will provide better dexterity and tactility for appropriate tasks. Thickness is usually measured in millimetres or mils, ranging from 0.06mm to 0.23mm, or 2-9 mil. For example, the Skytec TX424 has a thickness of 0.10mm, providing basic chemical protection against splashes in industrial or lab environments. Handling more aggressive chemicals for longer periods of time would require a thickness of at least 0.12mm, such as the Skytec Teal.

As colour is often used to identify specific characteristics of the single-use glove, it can act as a guide for applicational use. For example, the food industry typically uses blue whilst tattooists almost exclusively prefer black products (Skytec TX524). The reason could be something as simple as visibility – automotive users often adopt orange options to make oils easier to see.

If the wearer requires an element of grip for the task, a raised textured pattern can help with applicational use. This can be applied on the fingertips or on the entire glove allowing liquid to flow across, resulting in a better grip in wet or oily conditions. These products are more durable as they’re directed towards the industrial market.

This measures the amount of force required to break a glove. The higher the tensile strength, the stronger the glove. However, the highest is not necessarily the best as high tensile strength gloves are stiff and difficult to wear.

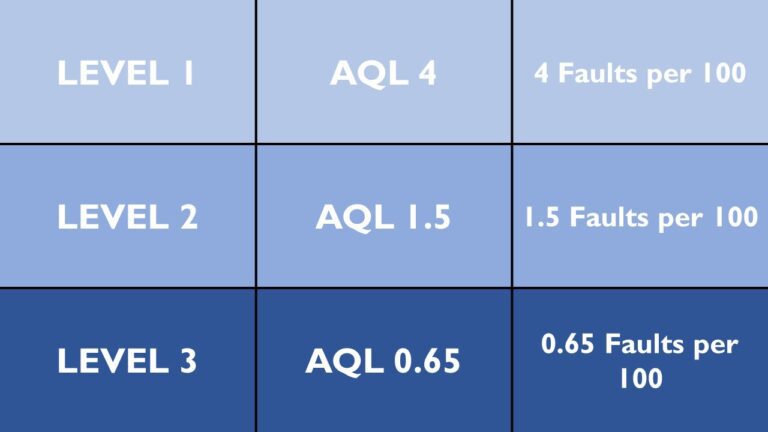

To ensure an effective barrier against liquids and micro-organisms, disposable gloves are rigorously tested before being brought to market. The key test for this is the Acceptance Quality Level or AQL, including the air and water leak test. The rating denotes the number of faults per 100 gloves – naturally, the lower the better!

Single-use products are an obvious target for sustainability efforts, which are increasingly becoming a part of all business’ considerations. This not only demonstrates a company’s commitment to environmental stewardship but also aligns with global efforts to combat the ever-growing plastic pollution crisis.

Both Showa and Skytec offer bio-degradable solutions without compromising the quality of the glove. Our pick would be the TX4524 as an alternative option.

When selecting the product, it is important to be led by the task it will be used for. For example, handling electrical components will carry a lower risk of glove permeation but a greater need for dexterity, hence a medium thickness with ESD properties would likely be the best option.

The key factors to look out for are the glove thickness and its suitability for industrial or medical applications.

If you have any questions or enquiries, please don’t hesitate to get in touch via our contact form below, or give the office a call on 01625 858008.

Sign up to our mailing list and keep up to date with all the latest products, deals and discounts!

This company undertakes to supply only safety equipment and/or related services that fully comply with the standards and regulations and claims made relating to those products and/or related services. Where appropriate, this company will maintain up to date technical files and associated documentation to ensure that regulatory compliance information can be supplied upon request.

Where products are sourced from external organisations which hold technical files relating to the products being offered, this company will request confirmation that these files are current, complete, contain appropriate conformity assessment information and, where relevant, regulatory compliance certificates and will take all necessary steps to confirm the validity of the compliance documentation held by that external supplier in respect of the products being sourced.

Where services are provided related to safety equipment sourced from external organisations, this company will maintain approval from the manufacturer that the services provided are assessed and approved by the external organisation.